English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Sany Mounted Boom Concrete Pump Truck

Send Inquiry

The Sany Mounted Boom Concrete Pump Truck is a high-quality concrete pump truck launched by Sany Heavy Industry, integrating German Putzmeister technology.

Sany Mounted Boom Concrete Pump Truck Description

The Sany Mounted Boom Concrete Pump Truck is a high-quality concrete pump truck launched by Sany Heavy Industry, integrating German Putzmeister technology. It boasts industry-leading R&D and manufacturing capabilities, utilises advanced production techniques, and adheres to a rigorous quality control system to ensure that every pump truck delivers exceptional performance and reliability. Its boom is constructed from high-strength alloy steel, featuring a robust structure and excellent fatigue resistance. The product is widely used in various fields such as building construction, municipal engineering, and bridge construction, significantly improving construction efficiency and concrete pouring quality.

Sany Mounted Boom Concrete Pump Truck Introduction

Sany Mounted Boom Concrete Pump Trucks have established a leading position in the concrete pumping equipment sector due to their outstanding performance and reliability. Equipped with high-capacity, high-pressure pumping systems, Sany Mounted Boom Concrete Pump Truck efficiently transport concrete to meet the demands of large-scale projects. Sany continuously innovates in boom design, adopting advanced boom vibration reduction technology and intelligent control systems to effectively reduce boom vibration during pumping, thereby enhancing construction stability and safety. The Sany boom pump truck also features energy efficiency and environmental friendliness, achieving reduced fuel consumption and operational costs through optimised hydraulic systems and engine power matching.

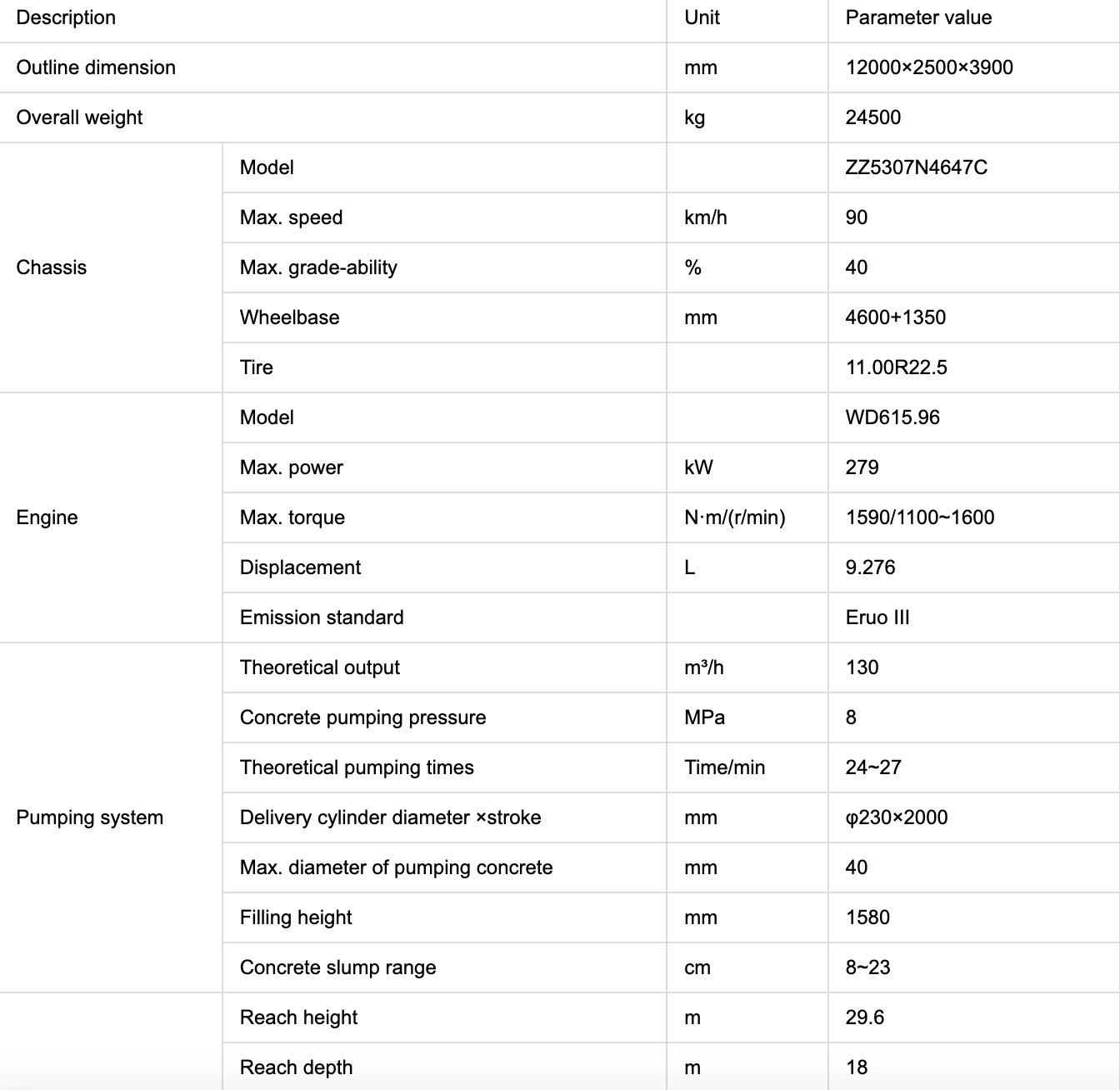

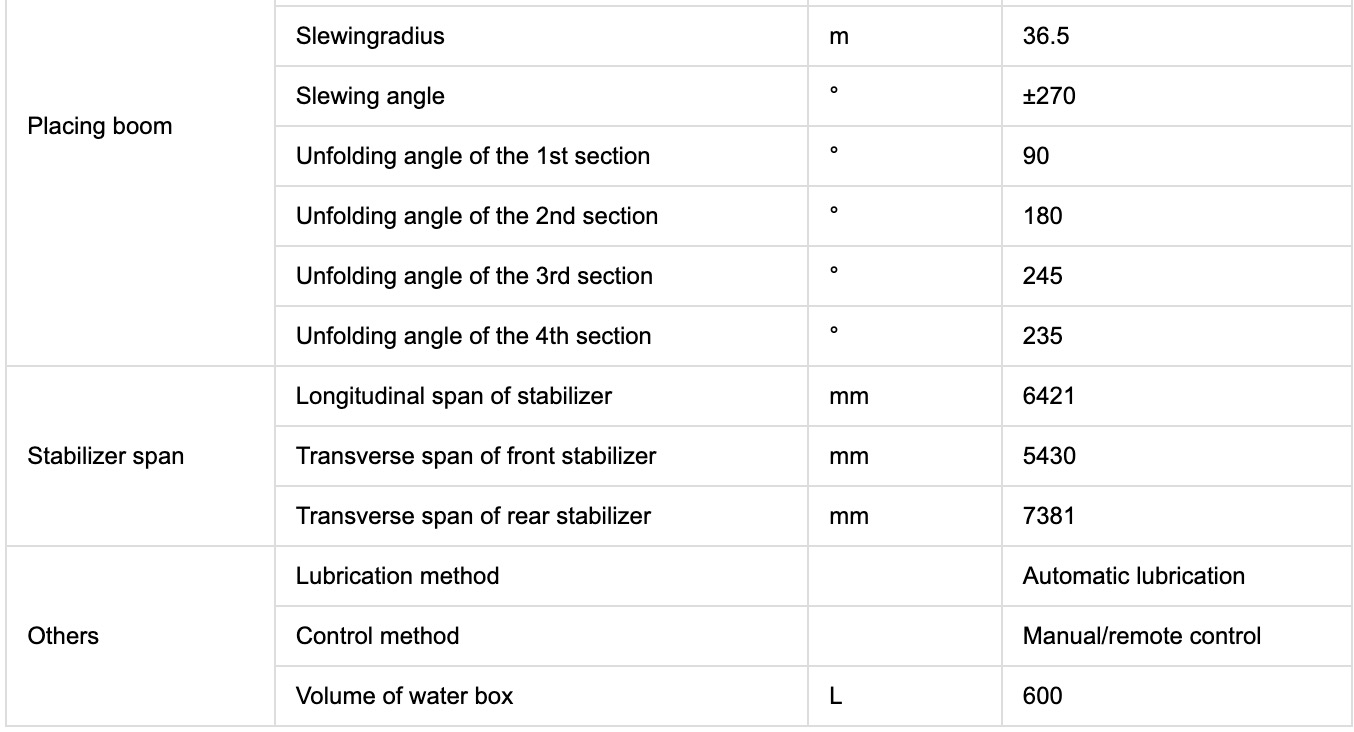

Sany Mounted Boom Concrete Pump Truck Specifications

Sany Mounted Boom Concrete Pump Truck Details

Large boom design and manufacturing technology: Sany's boom undergoes strict quality control at every stage from R&D, prototyping to mass production, ensuring structural durability and reliability.

Multiple advanced technologies: Sany's boom pump truck integrates various advanced technologies, such as one-button boom positioning technology, intelligent boom vibration reduction technology, energy-saving technology, and rotational anti-sway control technology. The intelligent boom vibration reduction technology, integrated with Putzmeister technology, effectively reduces boom vibration during pumping, with amplitude reduced by 50%; the energy-saving technology, integrated with Putzmeister technology, achieves 29 directional changes per minute (at a system pressure of 12 MPa), improving pumping efficiency by 25% and reducing fuel consumption by 10%; the rotational anti-swing control technology uses rotational braking technology, reducing boom rotational swing amplitude by 60%.

Highly wear-resistant components: The delivery pipes of Sany boom pump trucks adopt a double-layer composite structure, with the discharge port/transition sleeve also featuring a double-layer composite structure. The inner sleeve is made of special steel, the concrete piston is pressure-resistant, heat-resistant, and wear-resistant, the eyelet plate/cutting ring adopts a double-layer composite structure, and the inner layer of the delivery cylinder is chrome-plated with a hardness exceeding HV900.

Fault self-diagnosis technology: Sany boom pump trucks are equipped with fault self-diagnosis technology, capable of real-time monitoring and diagnosis of over 150 faults, effectively reducing troubleshooting time by 70%.

Sany Mounted Boom Concrete Pump Truck applications

Sany Mounted Boom Concrete Pump Trucks are widely used in various fields such as building construction, municipal engineering, bridge construction, railway/tunnel construction, and water conservancy and hydropower projects. Its large boom design and efficient pumping system can meet concrete delivery requirements in various complex construction environments. The Sany boom pump truck can quickly and stably deliver concrete in large-scale construction projects, improving construction efficiency and ensuring engineering quality. The Sany boom pump truck can also be used for emergency rescue and special engineering operations, with its flexible boom operation and powerful pumping capacity providing reliable solutions for various construction challenges.